JBT Launches Simplified, Sustainable and Data-Driven CoreTakr Flex Technology Solution

July 1, 2021 | 4 min to read

CHICAGO, IL — JBT Corporation , a leading technology solutions provider to the global food and beverage industry, announces the launch of JBT FoodTech’s CoreTakr Flex™, an intelligent and flexible robotic decoring technology with product data management.

The new and improved CoreTakr Flex™ includes fully automatic decoring solutions coupled with a manual infeed for produce such as iceberg lettuce, radicchio romaine lettuce, celery and others, amounting to 15 different leafy greens varieties. CoreTakr Flex™ is capable of decoring up to 2,400 heads per hour through its semi-automatic solution. By implementing the CoreTakr Flex™ system, companies will benefit from reduced waste, a decreased carbon footprint, a continuous reconfigurable outfeed.

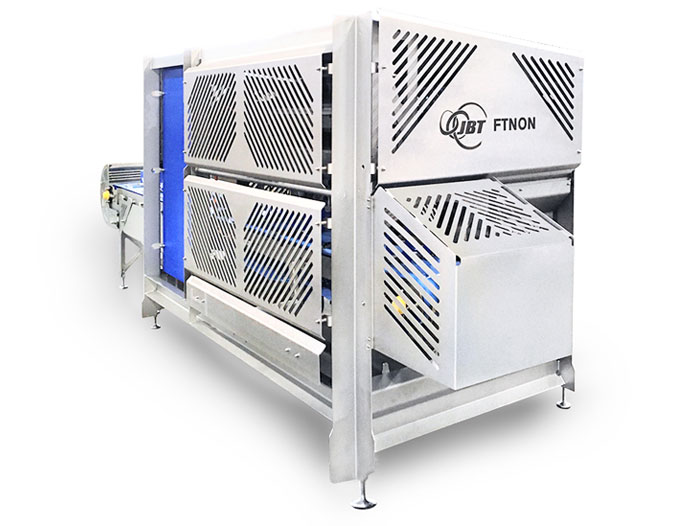

CoreTakr Flex™ utilizes the robotic systems of JBT’s FTNON. FTNON automates repetitive human labor tasks in fresh food applications in a safe and extremely hygienic way, while also capturing a wealth of useful data. Data collection includes production overviews, raw material data and details of? the incoming product used to inform the robot decoring system. Furthermore, process data and machine data are stored and used to predict maintenance, maximize machine effectiveness and optimize product quality.

“We are thrilled to launch CoreTakr Flex™, a technology that will provide our customers the safest and most advanced solution on the market,” said Carlos Fernandez, Executive Vice President of JBT Corporation and President, Diversified Food and Health. “By adopting CoreTakr Flex™, customers are investing in their business and in the planet by adopting a sustainable solution that reduces waste and increases yield and quality, getting the most value out of each product.”

JBT FoodTech’s commitment does not end with the purchase of the CoreTakr Flex™ system, but remains ongoing during the life of the equipment. JBT FoodTech prides itself on being a full-service partner, going beyond simply supplying the equipment to provide the best customer care, process knowledge, safety and support for each of their customers. Through JBT’s PRoCARE® services, customers can prevent unexpected costs through smart, purposeful and timely maintenance based on unmatched knowledge and expertise. PRoCARE service packages are offered in various service levels, depending on production and cost management requirements.

CoreTakr Flex™ is compatible with the CE machine guidelines. All potentially hazardous areas of the machinery are fenced, locked and non-reachable during operation, only to be unlocked by a safety signal that kills the power. In cleaning mode, belts can move slowly with the robot section completely shut down. Emergency buttons are placed on the control cabinet and the robot section.

To learn more about JBT’s varied fresh-cut solutions, please visit https://www.jbtc.com/foodtech.

###

About JBT

JBT Corporation (NYSE: JBT) is a leading global technology solutions provider to high-value segments of the food & beverage industry with focus on proteins, liquid foods and automated system solutions. JBT designs, produces and services sophisticated products and systems for multi-national and regional customers through its FoodTech segment. JBT also sells critical equipment and services to domestic and international air transportation customers through its AeroTech segment. JBT Corporation employs approximately 6,200 people worldwide and operates sales, service, manufacturing and sourcing operations in more than 25 countries. To learn more about JBT FoodTech, connect with the company on Facebook, Twitter and LinkedIn.