Breaking New Ground: Robots for Processing Avocados

March 26, 2024 | 6 min to read

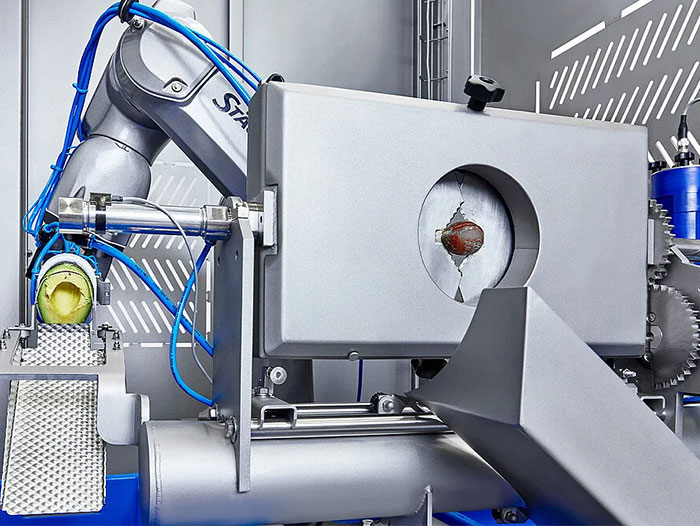

In collaboration with the food processing industry and Stäubli, KRONEN GmbH has introduced an advanced robotic solution for cutting, pitting, and peeling avocados, which enhances hygiene, efficiency, and yield. Demonstrated at the Anuga FoodTec trade show in March, this automation addresses ergonomic strain from manual processing. The system can process up to 1,000 avocados per hour, featuring integrated robots designed for easy cleaning, supporting a hygienic food production environment.

In cooperation with the food processing industry and the robotics supplier Stäubli, KRONEN GmbH has developed a unique solution for cutting, pitting and peeling avocados. This automated robot-based solution offers a multitude of advantages compared to conventional processing: It is extremely hygienic, reliable and flexible and constantly achieves top-quality results and a high yield. Another reason for developing a machine-based solution is the fact that manual processing requires a constant turning movement, which puts a great deal of strain on employees’ wrists. In March, this new solution was demonstrated live alongside a number of other new innovations at the Anuga FoodTec trade show in Cologne.

Automation plays an important role in the food industry. It maximizes hygiene, which is a fundamental requirement in the industry and in terms of consumer safety and product shelf lives. It also becomes increasingly important within the context of a skilled labor shortage.

“In the case of avocados, which are very sensitive, you may initially think that a machine-based solution is not possible. Here at KRONEN, however, we have decades of experience in food processing, even with sensitive products, and we invest a great deal in research and development to advance our customers with innovative solutions,” states Stephan Zillgith, Managing Director of KRONEN. “In this case, manual processing is not ergonomic and cannot achieve better results. The quality and yield achieved by the robotic solution are just as high, if not better, which is why we chose to develop this brand-new solution.”

Perfect avocados: completely reliably, hygienically and efficiently

The new and unique robotic line can be used to peel, halve and pit avocados gently and efficiently. If needed, the system can also be adapted to process different types of fruit that are suitable for robotic processing in the middle segment.

Depending on the capacity required, several robots can be used simultaneously. Three robots, for example, are able to process up to 1,000 avocados per hour. A wide variety of additions can also be introduced to further extend the line, for example a cutting machine such as the GS 10-2 belt cutting machine to subsequently cut the peeled, halved avocados into slices.

The avocados are placed in an inlay tray by an employee. The robot(s) then perform(s) the individual processing steps in a fully automated procedure:

• First, the robot removes the avocado with a grabber specially adapted to the fruit and uses a rotating movement on a pitting unit to remove the pit from the first half.

• The knives cut the flesh in half and clamp the pit.

The avocado is then peeled. Next, the robot removes the peel from the flesh by moving it over the peeling knife.

Another employee checks the product for skin and stone debris and natural damage as it leaves the system. The good product can be collected in crates or discharged via a belt depending on the capacity and customer requirements.

The system features integrated Stäubli robots with specially treated surfaces for optimal cleaning. It has its own separate safety housing and is equipped with remote maintenance technology, meaning that customers can make the most of quick and direct support from a KRONEN service employee if required.

To be suitable for automatic processing, the avocados must have a degree of ripeness that corresponds with a pressure value of 0.2 N/mm² to 0.8N/mm² (hardness measured with a penetrometer)

Watch the video: www.kronen.eu/video-avocado-robot

Hygienic processing from A to Z: washing, drying, peeling, cutting, packaging

In addition to this new innovation, KRONEN also showcased a number of other new food processing machines at the trade show, for example its HEWA 3800 HELICAL washing machine, which was launched last year. When designing the machine, KRONEN placed a special focus on hygienic design and set new standards in this area.

As a result, the HEWA guarantees an undamaged, optimally cleaned product that can be disinfected with a washing additive if required. KRONEN’s HELICAL washing system ensures that both floating and sinking products move through the wash tank in a spiral pattern, covering a distance up to ten times longer than the tank. Due to the ideal distribution, the product is loosened up and constantly rinsed completely during the cleaning process. Products are therefore washed thoroughly and gently, water consumption is considerably reduced, and the machine is ideal for a wide range of applications.

The HEWA 3800 is used to pre-wash, wash, disinfect, mix, treat and rinse lettuce, fruit and vegetables and can process up to 2500 kg of product per hour. It is ideal for products and applications such as:

• Lettuce (e.g. baby leaf, iceberg): cut and whole leaves

• Vegetables: cut and whole

• Herbs (e.g. parsley, chives): loose and in bunches

• Fruit (e.g. pineapple, melon): cut and whole

• Others: other leafy products (e.g. spinach), tuber products, pulses and mushrooms, as well as seaweed or kelp

Watch the video: www.kronen.eu/video-hewa3800

Further KRONEN machines at the Anuga FoodTec:

New product: Tona V cutting machine

• New product: MMC manual melon chunk cutter

• GS10-2 belt cutting machine

• KUJ-HC 220 and KUJ-V cube, strip & slice cutting machines

• PL 40K potato peeling machine

• AS 6 and AS 4 apple peeling and cutting machines

• PDS4L pepper coring and dividing machine

• KS-100 Plus lettuce and vegetable spin-dryer

• FLEX M packaging machine

About KRONEN GmbH

KRONEN is a family-managed globally operating producer and supplier of stand-alone machines, special-purpose machines and high-tech processing facilities for the fresh-cut industry. The product portfolio of KRONEN and its partners covers fruit, vegetable and lettuce processing: from preparing, cutting, washing, drying, dewatering, peeling and sterilizing right through to packaging. KRONEN additionally offers machines for the processing of meat and fish, special vegan products, baked goods and pet food. The company, which is based in the German town of Kehl am Rhein and has a second production site in the nearby town of Achern, currently employs more than 130 members of staff, has representatives in over 80 countries worldwide and supplies its products to more than 120 nations all over the globe. With more than 45 years of experience in food technology, KRONEN prides itself on its quality awareness and constantly strives to achieve the best possible solutions in its day-to-day work. The machine manufacturer focuses on taking a sustainable, holistic approach toward the hygienic, reliable and resource-friendly production of fresh foods. KRONEN considers itself to be a think tank that provides innovative solutions to benefit its customers and meet all their needs. It guarantees top-quality advice and planning expertise in close cooperation with the industry and research establishments.